Advanced SRV Wear Testing

Savant Labs have expanded its SRV testing capabilities for lubricating oil and grease testing. SRV is a valuable tool in tribological research of base oils, additives, formulated lubricants, greases, and more. The name SRV has become synonymous with innovation in the tribological analysis of lubricants and materials. The initials are derived from the German; Schwingung (oscillation), Reibung (friction), and Verschleiss (wear).

SRV measures the physical interactions between a lubricant and two specimens in a loaded contact and offers dual motion capabilities including oscillation and rotational modes. This method of testing is used to demonstrate performance across a broad range of applications for automotive, aerospace, semiconductor, biomedical, industrial, and more.

All standard SRV tests are in compliance with DIN, ASTM, and ISO. Most recently, the SRV test is now

part of the NLGI’s new High-Performance Multiuse (HPM) Grease

specification for high load (HPM+HL) certification.

All standard SRV tests are in compliance with DIN, ASTM, and ISO. Most recently, the SRV test is now

part of the NLGI’s new High-Performance Multiuse (HPM) Grease

specification for high load (HPM+HL) certification.

The SRV Equipment

and Uses

The SRV equipment is completely PC controlled (with manual system override), offering infinite programming flexibility within design specifications. Dynamic changes in the load, temperature, frequency, and stroke can be programmed to occur at preset times and rates during the test. The environment in the test chamber (temperature and atmosphere) can also be controlled.

The SRV can be used for:

- Fundamental research in tribology

- Lubricant and material development

- Friction and wear analysis of lubricants, materials, and bonded coatings

- Analysis of EP properties of oils and greases

- Analysis of stick-slip properties

- Research in fretting corrosion and other phenomena

- Oxidation stability and high-temperature performance of oil and greases

- Evaluating sub-zero lubricant properties

- Studying friction and wear behavior of fuels

The oscillation and rotation modes provide the ultimate in flexibility stresses that can be readily simulated on the SRV to match actual field conditions of:

- Oscillating friction

- Sliding friction

- Rolling friction

- Forming friction

Our most requested standard industry methods, for the SRV are ASTM D5706, ASTM D5707, ASTM D6425, ASTM D7594, DIN 51834, and others.

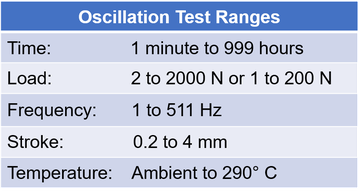

The table references the mode test ranges:

The SRV is ideally suited to help

manufacturers satisfy their quests for peak performance, more rapid

product development, and cost reduction.

In case you missed it, our On the Horizons Q3 2020 edition highlighted an

additional article on Wear Preventive Characteristics including

Extreme Pressure Four-Ball and Four-Ball Wear.

The technical team at Savant Labs has a deep understanding of wear

testing. We can help you define a test slate and analyze the data in a

concise and understandable format. Contact us for more information or request a quote for your next wear

testing project.